LITHO

(LITHOGRAPHIC) PRINT

LITHO

(LITHOGRAPHIC) PRINT

Lithography print is best suited for longer print runs. Our litho print services deliver some of the highest quality print for products such as packaging, posters and magazines.

At Dornans, we have the latest sheet-fed offset litho presses. These machines are extremely intuitive, with the capacity to print up to six colours. They’re so specialist, they even have the capability to print fine art reproductions. Furthermore, our presses are versatile enough to print both sides in one pass. This allows us to create bespoke and unique results for clients of all shapes and sizes. No matter what your product, you’ll be receiving the finest quality print. No slip ups, no mess. Just first class results to ISO quality standard.

With over 170 years experience, we have the in-house expertise and know-how to understand your requirements and deliver a product that exceeds your expectations. We have strict quality control measures in place to ensure that we deliver on our customer promise; To provide printing excellence.

more than just print

Our passion for print is matched only by our drive to deliver industry leading customer service. Whatever your printing requirements, we’ll take a consultative approach, to ensure that you’re receiving the best print for your requirements.

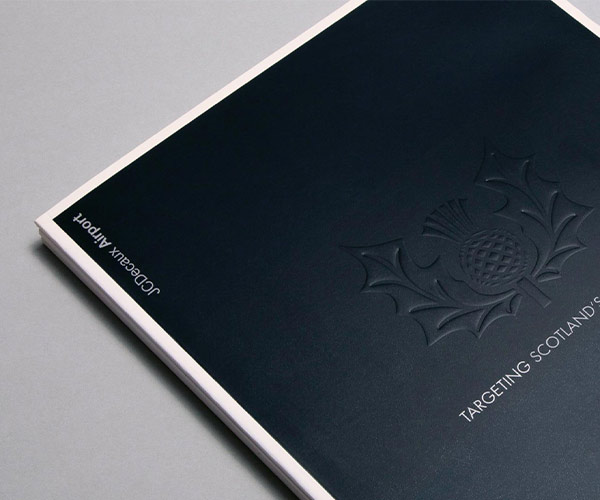

Our printing services are supported by our dedicated in-house finishing service. We’re able to finalise your print so it’s perfectly ready for you upon delivery. We offer laminating, binding, embossing, saddle stitching and much more.

Our creative in-house design team will deliver a service that reflects your brand and makes an impression with your customers.

WHY CHOOSE LITHO PRINT?

Looking to make a real mark with your corporate brochure? Or do you have a bespoke cut to shape requirement for product packaging. Litho print is an extremely high quality method, that is ideal for print that needs to be perfect. .As well as this, the benefits of litho print are:

– Perfect for high volume runs

– Fast turnaround

– Highest quality print

– Wide variety of paper stocks and weights

– Exceptional colour reproduction

– Can have a range of finishing applied

OUT LITHO PRINT PRODUCTS

CLIENTS WE HAVE WORKED WITH

Our reputation is built on quality, service and technical excellence.

What Is Lithographic Printing?

Lithographic printing can go by many names, such as litho, lithography, offset, planographic and planography printing. We use lithography to achieve a high volume of high-quality prints, lithographic printing is commonly used for prints that require multiple, if not thousands of the same item. This makes it the perfect printing method for leaflets, brochures, flyers, and other marketing material.

In litho printing, the printed image is achieved through a carefully managed chemical balance between water and oil-based inks. The image areas of the plate are great at receiving the ink and repel the water use in Lithographic Printing; whereas the non-image areas are water receptive. The water wets the non-image areas of the plate and prevents the ink from adhering.

The process also allows for very high quality and fine detail with colour reproduction as fine as 250 lines per inch. So if you’re looking for high volume printing without compromising on quality lithographic printing could the right choice for you.

We regularly produce large volume runs for our clients that range up to the thousands and can deliver this quickly and cost-effectively every time. So if you’re looking for a litho printer, look no further.

The Lithographic Printing Process

We’ve been a lithographic printer for over 100 years so our process has been refined and improved continuously, we regularly invest in state of the art litho printing machinery and equipment. Because of this we are able to offer each and every client the flexibility to meet tight deadlines and a streamlined work-flow.

In simple terms the litho printing process is:

- Design or images are provided, these are transferred to printing plates.

- The printing plate is kept dampened. The ink is applied to the plate, but will be repelled from the dampened areas (non-imaged areas).

- As the printing cylinder begins to rotate the ink is transferred onto the rubber blanket cylinder.

- With the ink now being transferred onto the rubber blanket cylinder, it is then pressed onto the chosen paper or card whilst being pushed through the machine.

“We have worked with Dornans for nearly a decade now because they deliver the highest quality and service every time, they have become an integral part of our production team”

“Dornans were referred by our Creative Agency and we were delighted with the quality, service and results from the campaign”

“Dornans consistently deliver to our tight deadlines and always with exceptional quality and brilliant service”

“Dornans always find solutions to produce our bespoke print requirements to exceptional high standards”

“We have worked with Dornans for a few years now and the quality and service has been excellent. Sustainability is important for us, so we have moved to using 100% recycled paper and environmentally friendly inks with no detriment to the quality of the finished product.”

Get in touch with us today to discuss your Litho print requirements.

GET IN TOUCH!

GET IN TOUCH!